Technical Overview

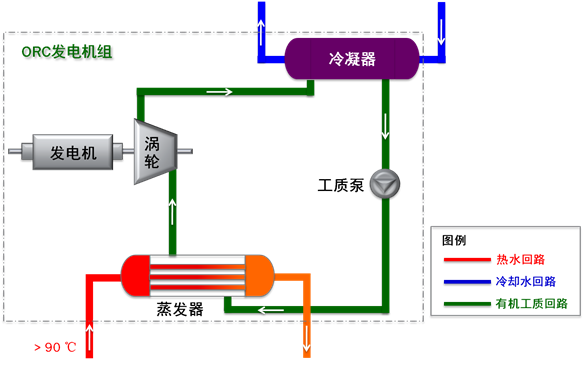

The Organic Rankine Cycle (ORC) is a Rankine cycle with low boiling point organic matter as the working fluid, which is mainly composed of four major parts: waste heat boiler (or heat exchanger), turbine, condenser and working fluid pump. The organic working fluid absorbs heat from the waste heat flow in the heat exchanger to generate steam with a certain pressure and temperature, and the steam enters the turbine machinery to expand and do work, thereby driving the generator or dragging other power machinery. The steam discharged from the turbine is released into the cooling water in the condenser, condensed into a liquid state, and finally returned to the heat exchanger with the help of a working fluid pump, and so on.

Organic working fluids (such as R123, R245fa, R152a, ethyl chloride, propane, n-butane, isobutane, etc.) are mostly used as circulating working fluids in low-temperature waste heat power generation.

Product Introduction

The expander technology forms used in the ORC power generation system mainly include: axial turbine, radial turbine, screw expander, and scroll expander. Centripetal turbines have the advantages of high isentropic efficiency, large power range, and reliable operation. The modular design of the centripetal ORC generator set and the pipe connection design between the equipment make it meet the requirements of skid-mounted design, which is convenient for long-distance transportation and rapid assembly on site.

(1) The screw expander uses fluid to expand between the yin and yang screws, so the processing accuracy of the yin and yang screws is extremely high, although so, the main mechanical parts of the machine are only a pair of screws and cast steel shells, and its structural form is still very simple.

(2) It is a volumetric full-flow power equipment, which can adapt to superheated steam, saturated steam, and soda two-phase fluid working fluid;

(3) It can maintain stable operation and high operating efficiency within the range of 30%~120% change of heat source parameters, heat load and power;

(4) The power of a single machine is 15KW~3000KW:

(5) The equipment is compact and the construction amount is small;

(6) Easy to operate, simple to operate and maintain, long overhaul cycle: (6)

(7) There is no need to crank the car for starting. Low noise, stable, safe and reliable, fully automatic unattended operation.