Ammonia is a carbon-free flammable substance, and its combustion reaction is shown in the following formula.

2NH3+3/2O2=N2+3H2O(ΔH=-382.6kJ/mol)

The calorific value of ammonia when it is burned is not high, which is comparable to methanol, but the energy density of liquid ammonia is higher than that of batteries, and it can be used as a fuel.

The following is a comparison of the experimental combustion of natural gas and ammonia:

On the left is the combustion flame of natural gas, which is sky blue with sufficient oxygen and ammonia is yellow when burning.

Small-scale experiments and simulations of ammonia-coal mixed combustion technology

Combustion and flame propagation characteristics: Affects the ignition characteristics of pulverized coal, and the flame is far away from the burner nozzle

Flame morphology, temperature and radiation characteristics: the flame length of ammonia-coal mixed combustion is significantly greater than that of pure ammonia combustion alone, when the ammonia blending ratio is 60%, the heat transfer in the furnace is the smallest, which is about 3% lower than that of coal single burning, and when the ammonia blending ratio increases from 60% to 80%, the flue gas volume and flue gas velocity increase, resulting in an increase in heat transfer to the wall.

NOx generation and emission characteristics: 1) The location and mode of ammonia injection affect the formation of NOx. When ammonia is injected from the center of the burner, the NOx concentration is higher than that of coal burning alone (about 24% and 7%), while when ammonia is injected from the sidewall about 1.0m away from the burner, the NOx emission concentration is almost the same or slightly lower than that of coal burning alone, and when the ammonia is injected farther away from the burner outlet, the NOx concentration in the flue gas further increases. When ammonia is injected from the flame zone of the burner, with the increase of the proportion of ammonia blending, the position of NH3 reaction and the peak value of NO move to the downstream position, and when the proportion of NH3 blending is 20%, the NO emission is less than that of coal burning alone, when the ratio of NH3 blending is 20~60%, the NO monotonically increases with the increase of the proportion of ammonia blending, and when the proportion of NH3 blending is further increased to 80%, the NO emission will decrease to the level of 40%.

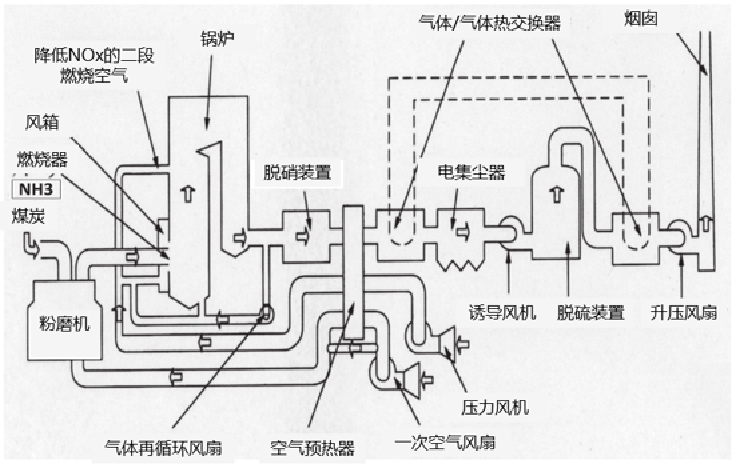

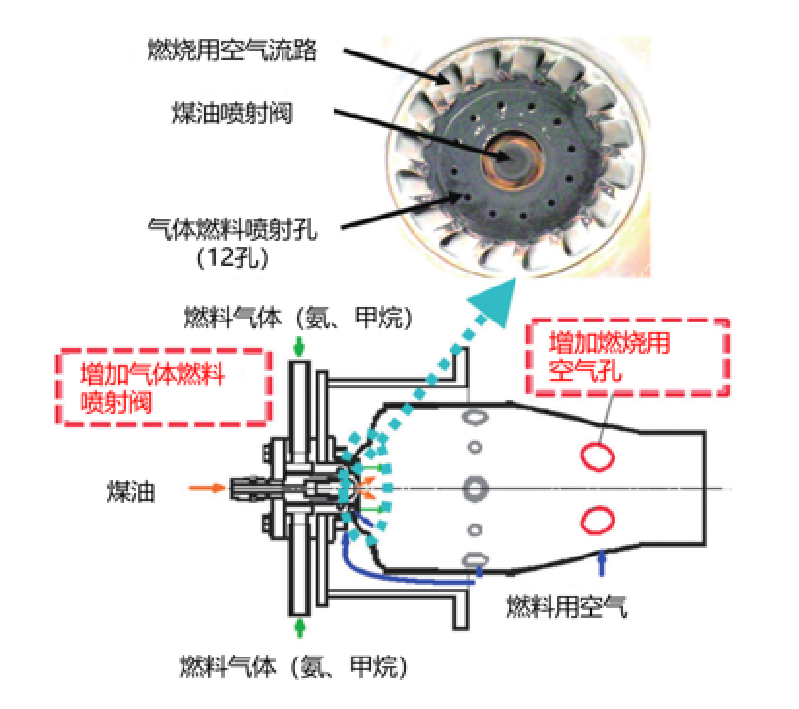

The design principle of the burner is basically designed according to the idea of the light burner. In the concentrated combustion part of the primary combustion zone, ammonia is decomposed into hydrogen and nitrogen, and in the secondary combustion zone, the decomposed hydrogen is combusted. The combustion temperature is lowered by secondary air, the generation of NOx is suppressed, and the unburned ammonia is completely combusted. Ammonia has the characteristics of slow combustion rate and low ignition. This problem has been solved by the development of a steam burner (pictured).

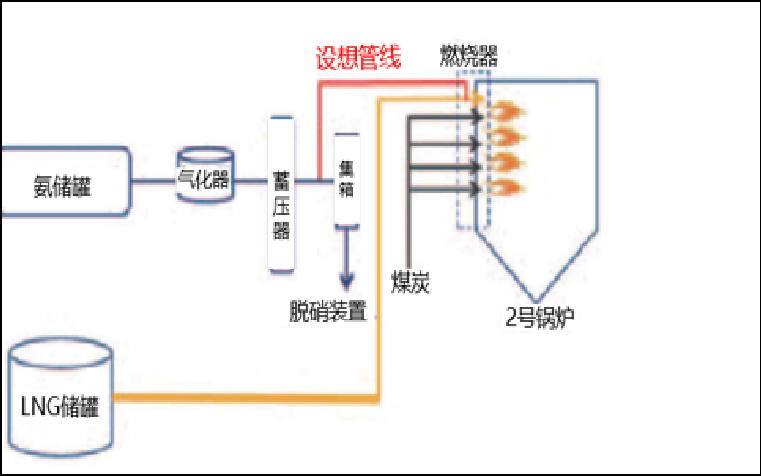

The photo shows a demonstration test of ammonia co-burning at a coal-fired thermal power plant in Shuidao, China, which was carried out at a power of 120 MW, and the ammonia injection used a burner that burned to treat BOG. Previously, it was feared that direct combustion of ammonia would lead to an increase in NOx values. However, the experimental results showed that the NOx value did not increase, but decreased slightly. This may be due to the role of ammonia as a reducing agent for the breakdown of NOx. In conclusion, it has been confirmed that even if the ammonia is burned directly, the NOx value will not increase.

The picture shows the 8.3MW pure ammonia burner jointly developed by the Energy Research Institute of Hefei Comprehensive National Science Center (hereinafter referred to as the "Energy Research Institute") and Wanneng Group, which is the first in China, was tested in the 300MW thermal power unit of Tongling Power Generation Co., Ltd. of Wanneng Co., Ltd., and the test results were successfully ignited at one time and operated stably for more than 2 hours. The successful ignition means that it is technically feasible to achieve the carbon reduction goal through ammonia-doped combustion in the boiler of coal-fired power units, marking the key progress of the ammonia energy comprehensive utilization power generation demonstration project.